Inventory management is a critical aspect of running a successful business, yet it can often feel like a challenging balancing act. From overstocking to stockouts, the complexities of managing inventory can impact the bottom line and customer satisfaction. In this blog post, we’ll explore various strategies and best practices for achieving an effective balance in inventory management.

The Impact of Poor Inventory Management

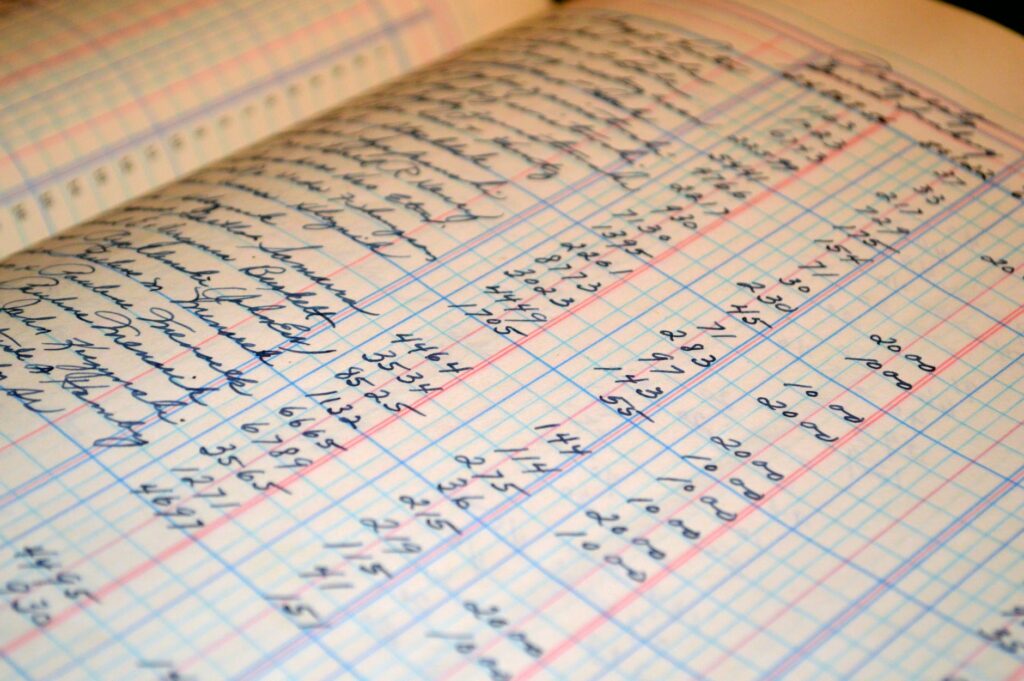

Poor inventory management can lead to various detrimental effects on a business, such as increased holding costs, reduced cash flow, missed sales opportunities, and dissatisfied customers. It’s essential to recognize the signs and consequences of inadequate inventory management to take proactive steps towards improvement.

Understanding Demand Patterns and Forecasting

A fundamental aspect of effective inventory management is understanding demand patterns and forecasting future needs. By utilizing historical sales data, market trends, and predictive analytics, businesses can make informed decisions about stock levels, ensuring that they meet customer demand without overstocking.

Just-in-Time (JIT) Inventory Management

Implementing a just-in-time (JIT) inventory management approach can significantly improve efficiency and reduce waste. By receiving goods only as they are needed in the production process or for customer orders, businesses can minimize excess inventory and associated holding costs.

Leveraging Technology and Automation

In today’s digital age, technology plays a crucial role in streamlining inventory management processes. Utilizing inventory management software, barcode scanning systems, and automated reorder triggers can enhance accuracy, efficiency, and real-time visibility into inventory levels.

Supplier Relationship Management

Establishing strong relationships with suppliers is vital for maintaining a well-balanced inventory. Collaborating closely with suppliers can lead to better lead times, pricing, and product availability, ultimately contributing to improved inventory management outcomes.

Categorizing Inventory Items

Categorizing inventory items based on their demand and value can aid in prioritizing management efforts. This approach allows businesses to allocate resources effectively, ensuring that high-demand or high-value items receive the necessary attention and focus.

Continuous Monitoring and Analysis

Continuous monitoring and analysis of inventory performance metrics are essential for identifying areas of improvement and making timely adjustments. Regularly tracking key performance indicators (KPIs) such as turnover rates, carrying costs, and stockout rates enables proactive decision-making.

Adopting Cross-Functional Collaboration

Effective inventory management requires collaboration across different departments within an organization. By fostering cross-functional communication and collaboration between sales, operations, and finance teams, businesses can align inventory management strategies with broader organizational goals.

Tailoring Strategies for Plastic Molding Companies

For plastic molding companies, customized inventory management strategies are vital for overcoming industry challenges. Dealing with diverse materials and components with varying storage needs and lead times requires integrating demand forecasting with just-in-time (JIT) inventory control. This approach helps mitigate raw material shortages or excess, ensuring efficient production. Leveraging technology for real-time tracking of molds and materials boosts operational efficiency. Building strong relationships with suppliers enhances supply chain reliability, meeting production schedules and client needs effectively.

Conclusion

Balancing inventory management is indeed a multifaceted challenge, but with the right strategies and tools in place, businesses can achieve optimal inventory levels, reduce costs, and improve customer satisfaction.

By understanding demand patterns, leveraging technology, and fostering collaboration, businesses can effectively navigate the intricacies of inventory management and position themselves for long-term success.

In conclusion, effective inventory management is not just about keeping shelves stocked; it’s about striking a harmonious balance that optimizes resources, minimizes costs, and maximizes customer satisfaction. Embracing these strategies can transform inventory management from a daunting task into a competitive advantage.

About the author

Hiee, Beautiful people. This is Yamini, Co-founder of Gyanvardaan.com. I am an enthusiastic writer. I am From Meg, The city of Beautify. I love to write and publish related to Tech and Lifestyle.